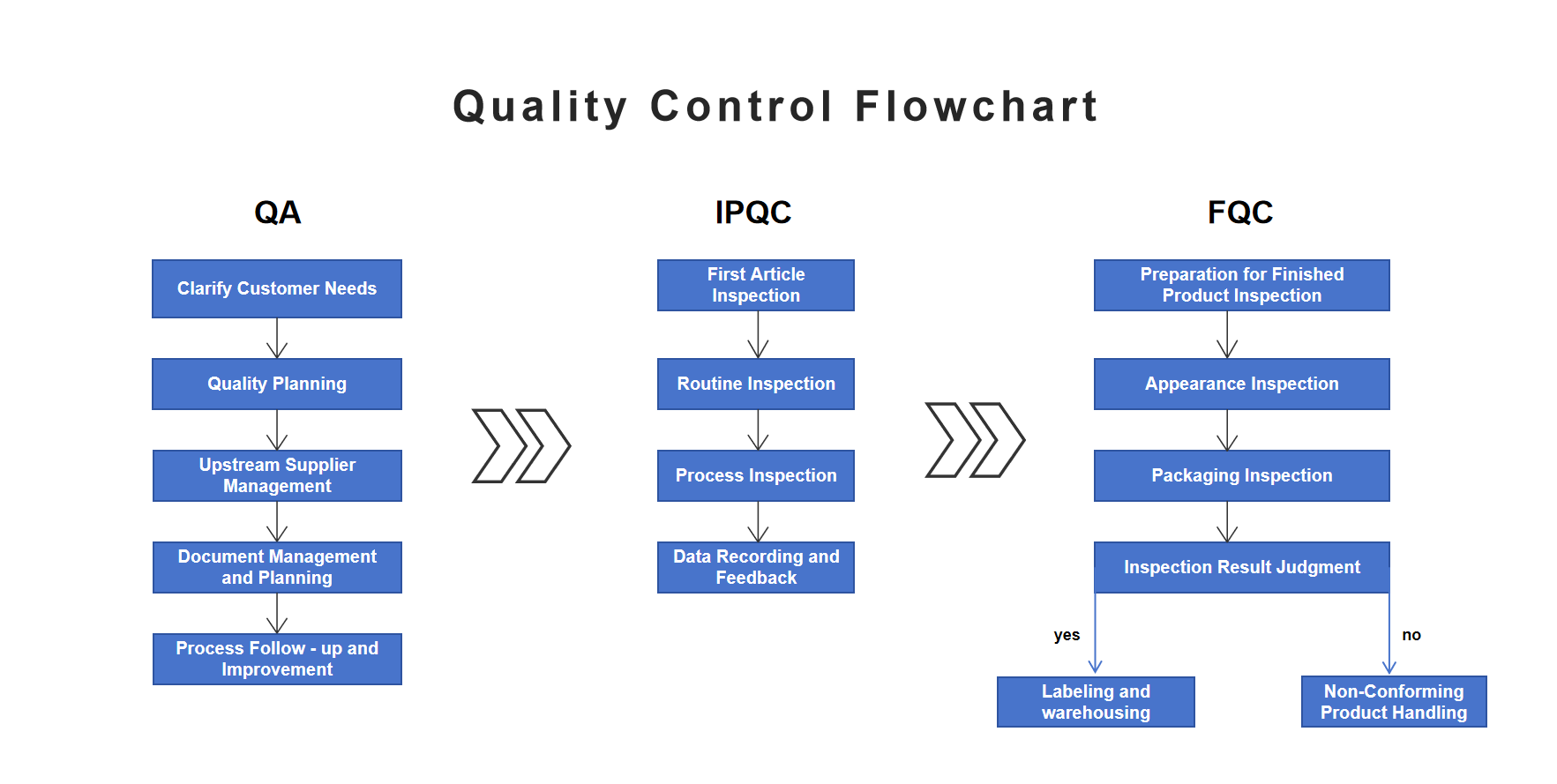

Easterglass has been awarded the ISO9001 quality management system certification recognized by the state and strictly adheres to relevant regulations for stable production. By fully implementing the quality management system, we ensure a high degree of consistency in every product leaving our factory, which has won wide acclaim from overseas customers.

We have established a full - process service system to enhance the customer purchasing experience. Moreover, we have meticulously crafted a quality management system to ensure that customers get excellent value for their money.

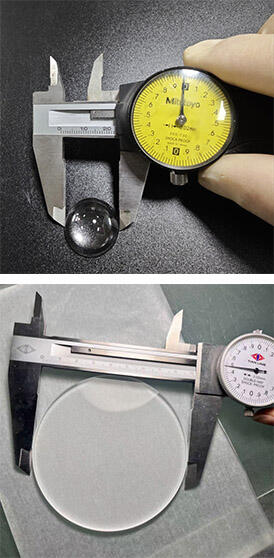

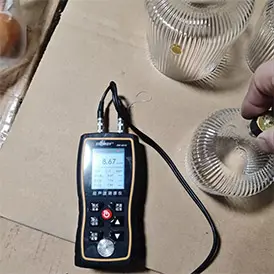

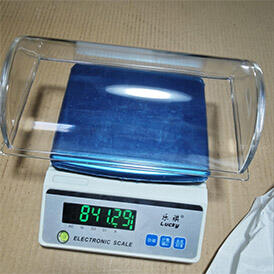

In terms of quality, we have detailed inspection standards, inspection procedures, and a variety of inspection methods tailored to customer requirements. Below are some pictures of our product inspections.

Temperature Resistance Test.

We heat the glass to 100 degrees Celsius and then place it into an ice-water mixture at 0 degrees Celsius. The glass do not break.

4J shock test.

We use a 0.5kgs iron ball, fall from a distance as 82cm, the glass do not break.

The most common measurement method is to use a caliper. We will measure the overall dimensions and detailed dimensions of the product according to the drawings and record them.

For products with special shapes, we will use an electronic measuring instrument to measure the special parts.

For pressed products, customers usually have requirements for the weight. Therefore, we will measure the weight of the glass during the first inspection and take this as the standard for subsequent inspections.

We usually turn on the light source and inspect the appearance and light effect of the glass in a bright environment.

We usually conduct manual inspections on the surfaces of all the glass.

For the installation of the glass, we will use a professional measuring instrument or a customized go-no-go gauge to conduct special inspections on the glass.

We often use a professional stress meter to detect the internal stress of the glass to ensure that the stress of each piece of glass has been removed.